AN901 REV. 10

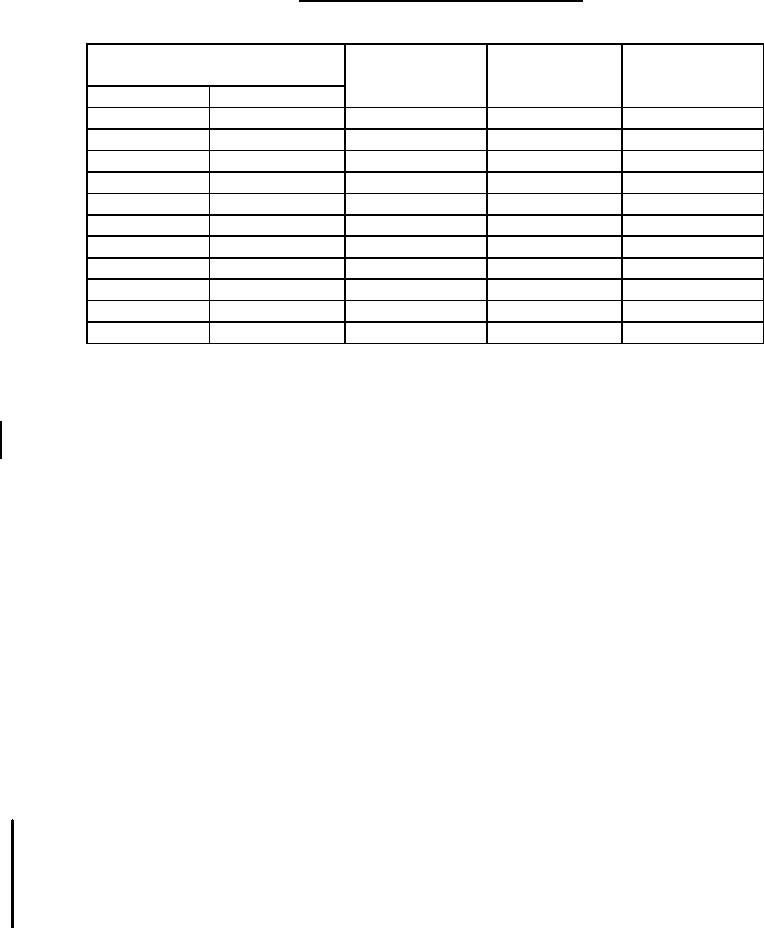

TABLE I. Gasket Dash Numbers and Dimensions

ØA

ØB

DASH NUMBER

TUBING

+.010

+.000

OD

-.000

-.010

ALUMINUM

COPPER

4A

4C

.250

.443

.683

5A

5C

.313

.505

.745

6A

6C

.375

.568

.808

8A

8C

.500

.755

.995

10A

10C

.625

.880

1.120

12A

12C

.750

1.068

1.370

16A

16C

1

1.318

1.620

20A

20C

1.250

1.630

1.870

24A

24C

1.500

1.880

2.120

28A

28C

1.750

2.255

2.495

32A

32C

2

2.505

2.745

NOTES:

1. Material: Aluminum, specification ASTM B209, Alloy 1100, temper H14.

Copper, specification ASTM B152/B152M Standard O60 cold rolled, soft annealed.

2. Finish: Copper, cadmium plate, specification SAE AMS-QQ-P-416, type II, class 3.

3. Color: Copper, yellow.

4. Heat treatment: Copper gaskets shall be annealed after fabrication and prior to plating.

5. Surfaces shall be smooth, flat and free from nicks and scratches.

6. Examples of part numbers: AN901-4A = Aluminum gasket for 1/4 OD tubing.

AN901-4C = copper gasket for 1/4 OD tubing.

7. Break all sharp edges and remove all hanging burrs and slivers which might become

dislodged under usage.

8. Dimensions in inches.

9. Changes from previous issue. The margins of this specification are marked with vertical lines

to indicate where changes from the previous issue were made. This was done as a convenience

only and the Government assumes no liability whatsoever for any inaccuracies in these

notations. Bidders and contractors are cautioned to evaluate the requirements of this document

based on the entire content irrespective of the marginal notations and relationship to the last

previous issue.

2