MIL-DTL-16685E

3.3 Resistance to accelerated aging. Packing shall withstand the test specified in 4.4.1

without hardening or undergoing any change which indicates deterioration.

3.4 Molding. The rounded, class 1, packing shall be capable of being readily molded or

prefabricated into packing sets. This capability shall be determined by the test described in 4.4.3.

3.5 Performance. Packing shall be capable of remaining tight indefinitely, and shall have no

deleterious effects upon the sheathing of electric cables or upon the metallic armor of electric

cables, where used against water, air, or gas at pressures from atmospheric to 25 p.s.i.g. (.1724

MPa) at temperatures up to 212 F (100 C). (see 4.4.2).

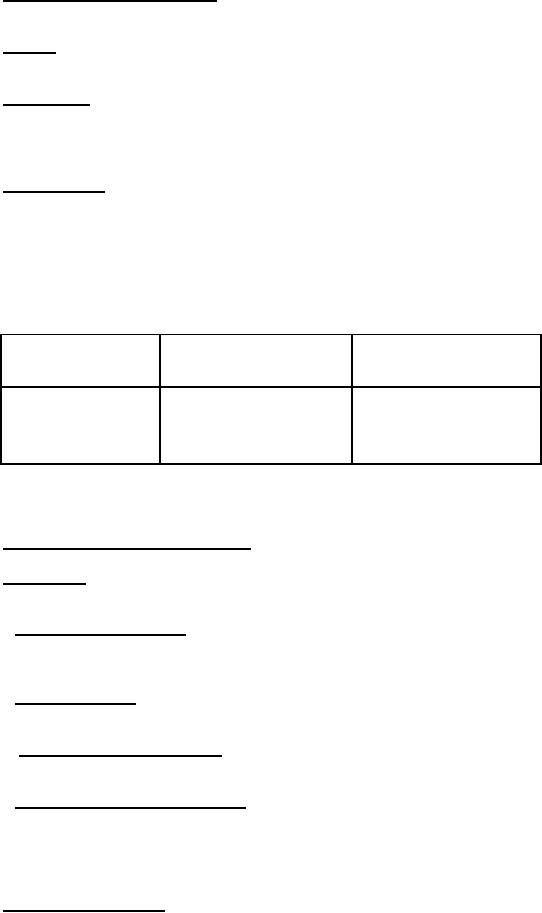

3.6 Compressibility. Packing shall be formed under the minimum pressures specified in

table II with the packing and molds maintained at a minimum temperature of 100 F (37.8 C).

When tested as specified in 4.4.3, the height shall be not less than 80 percent of the original

height. For packing, class 1, furnished in bulk, spools or reels, check compressibility of all

diameter of cable and packings in mold sizes equal to stuffing tube sizes C, L, R, and V,

respectively, in the above manner.

Table II - Molding pressures.

Minimum pressure

Type

Size

(p.s.i. of annular

area of packing)

AJ

600

I

KZ

400

I

AR

600

IA, II

S-Z

400

IA, II

4. VERIFICATION

4.1 Sampling for conformance inspection.

4.1 Sampling lot. All packing of the same class, composition, type, or size shall be

considered a lot for purposes of acceptance inspection.

4.1.2 Sampling for examination. Sample sets or spools shall be selected at random in

accordance with ASQ Z1.4 at Inspection Level I for the examination of 4.2.1. The Acceptable

Quality Level shall be 2.5 percent defective.

4.1.3 Sampling for tests. Sample sets or spools shall be selected at random in accordance

with ASQ Z1.4 at Inspection Level S2 for tests specified in 4.2.2.

4.1. 4 Sampling for compression test. A random sample of sets or spools shall be selected

from each lot in accordance with 4.1.3 and subjected to the test specified in 4.3.3.

4.1.5 Sampling for production check test. Three yards of rounded packing and two sets of

preformed packing from the first lot of each type and class and 54 in. (137 cm) of rounded

packing and one set of preformed packing from every tenth lot shall be selected from the same

class and type for the tests specified in 4.3. The samples shall be chosen so that over a period of

time a representative selection of sizes will be sampled.

4.2 Conformance inspection.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business