MIL-DTL-24293B

2.2.1 Specifications, standards, and handbooks. The following specifications and standards

form a part of this document to the extent specified herein. Unless otherwise specified, the

issues of these documents are those cited in the solicitation or contract.

FEDERAL STANDARDS

FED-STD-311

Leather, Methods of Sampling and Testing

(Copies of these documents are available online at https://assist.daps.dla.mil/quicksearch/ or from

the Standardization Document Order Desk, 700 Robbins Avenue, Building 4D, Philadelphia, PA

19111-5094.)

2.3 Order of precedence. In the event of a conflict between the text of this document and the

references cited herein, the text of this document takes precedence. Nothing in this document,

however, supersedes applicable laws and regulations unless a specific exemption has been

obtained.

3. REQUIREMENTS

3.1 Material. The packing shall be made of cattlehide leather.

3.2 Tannage. The leather packing shall be tanned with chromium salts without the use of

vegetable tanning materials.

3.3 Finish. The leather packing shall be full-grain with the flesh side smooth and free from

loose flesh. It may be lightly split or skived to facilitate impregnation.

3.4 Trim. The leather packing shall be in the form of belting butt bends as specified in

FED-STD-311.

3.5 Selection. When provided in the form of belting butt bends, the leather packing shall

have no defects such as deep cuts, damaged grain, open scratches, open grub holes, brands, hip

marks, or any other defects which effect a loss in cutting value greater than 6 percent of the total

area. When purchased in the form of finished packing, the leather packing shall be free from

defects.

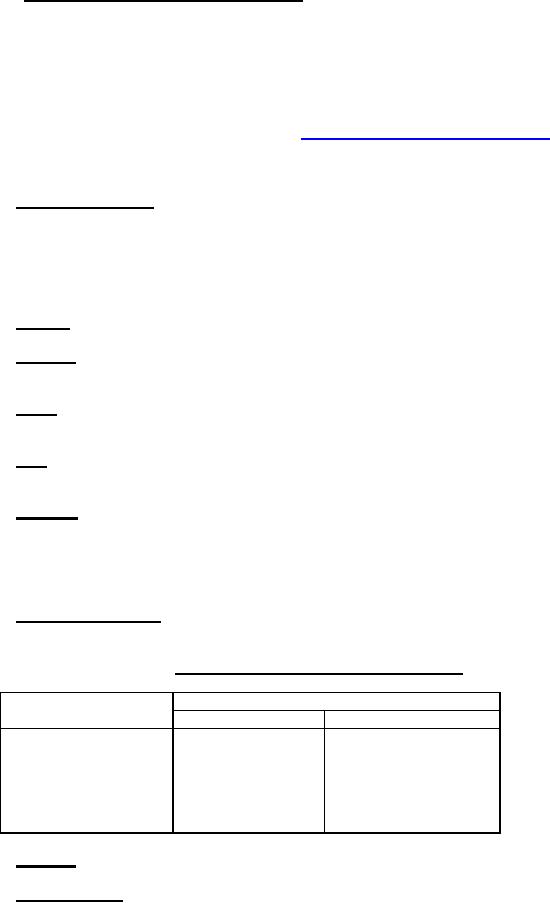

3.6 Thickness for weights. The leather packing shall be furnished in the thickness specified

for each weight shown in table I.

TABLE I. Thickness for each weight of leather packing.

Thickness

Weight

Minimum

Maximum

64ths inch

64ths inch

Medium

8 (.125)

10 (.156)

13 (.203)

Heavy

11 (.172)

Extra heavy

14 (.219)

17 (.266)

3.7 Cracking. The leather packing shall not crack (see 4.5).

3.8 Tensile strength. The tensile strength shall be not less than 2,500 psi (17.24 MPa) for

any one specimen (see 4.3).

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business