MIL-DTL-24293B

3.9 Elongation. The elongation under a load of 2,500 psi (17.24 MPa) shall be not more than

30 percent when tested with the long direction parallel to the backbone. When tested in the belly-

belly direction, the elongation shall not exceed the following limits (see 4.3):

Medium - 30 percent maximum.

Heavy - 35 percent maximum.

Extra heavy - 40 percent maximum.

3.10 Shrinkage. The reduction in area of the leather packing shall be not more than 5

percent (see 4.3.2).

3.11 Porosity. The impregnated leather packing shall show no leakage of water (see 4.3.3).

3.12 Chemical composition. The leather packing shall conform to the chemical composition

shown in table II (see 4.3, 4.3.1, and 4.3.5).

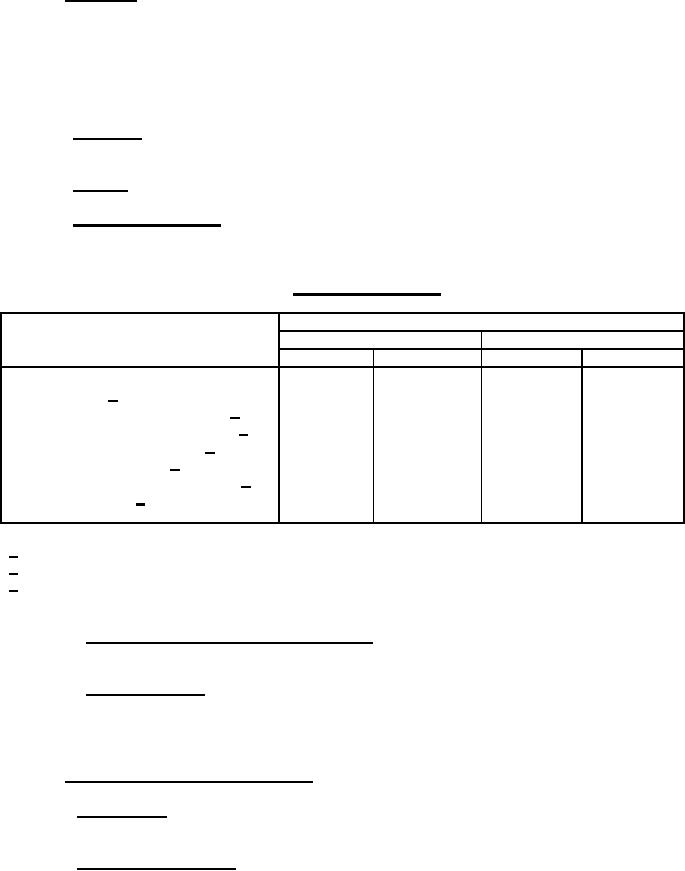

TABLE II. Chemical composition.

Percent by weight

Type I

Type II

Min

Max

Min

Max

Chromic oxide 1/

-----

4.5

-----

4.5

Grease (petroleum ether extract) 2/

20

8

8

15

30

-----

Impregnating wax (benzol extract) 2/

23

-----

0.30

-----

Chlorides as sodium chloride 1/

-----

0.30

Sulfates as sulfuric acid 1/

-----

0.30

-----

0.30

-----

35

-----

Total polysulfide polymer (Thiokol) 3/

-----

-----

-----

-----

Chloroform extract 3/

15

1/ Moisture, wax, and grease-free basis.

2/ Moisture-free basis.

3/ Determined on finished leather packing. Ash and all remaining chemical tests shall be

determined on a representative sample prior to application of polysulfide polymer.

3.12.1 Ash (moisture, wax, and grease-free basis). Ash shall be not more than 120 percent

of the chromic oxide (see 4.3).

3.12.2 Impregnating wax. The leather packing shall be impregnated with a wax having a

melting point within the range of 170 to 185 F (76.7 to 85 C).

4. VERIFICATION

4.1 Sampling for conformance inspection.

4.1.1 Inspection lot. All leather packing of the same type and weight presented at one time

shall be considered a lot for purposes of inspection.

4.1.2 Sample for examination. A random sample of leather packing units shall be selected in

accordance with table III from each inspection lot of material offered for examination of visual and

dimensional characteristics. Acceptance quality level (AQL) equals 1.5 percent defective.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business