MIL-DTL-25988C

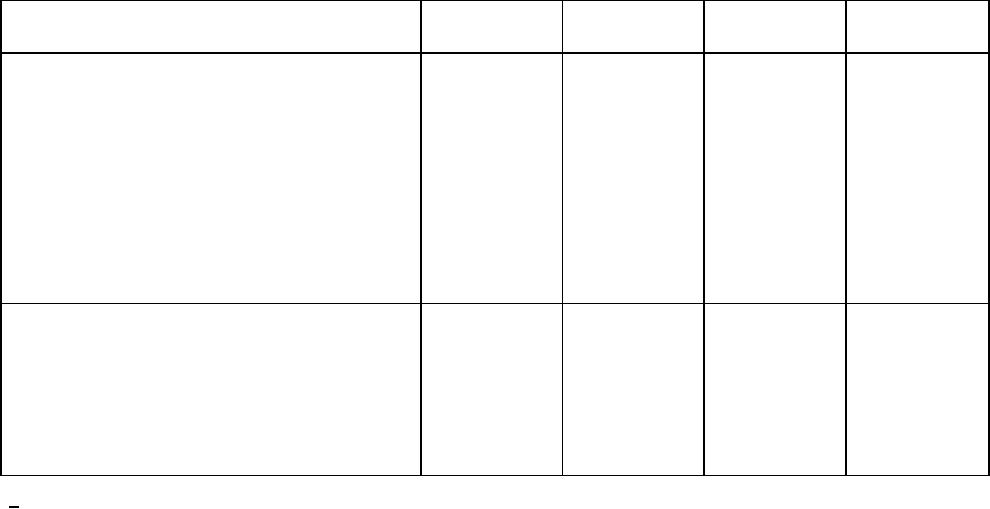

TABLE II. Physical properties, type I (O-rings) Continued.

Class 1

Class 1

Class 1

Class 3

grade 60

grade 70

grade 80

grade 75

After aging 70 hours in AMS 3021 @ the temperatures

302 ±5 °F

302 ±5 °F

302 ±5 °F

347 ±5 °F

indicated:

(150 ±2.8 °C)

(150 ±2.8 °C)

(150 ±2.8 °C)

(175 ±2.8 °C)

Hardness change, points, max.

±15

±15

±15

±20

Tensile strength decrease, %, max.

45

40

30

30

Elongation decrease, %, max.

30

25

15

20

Volume change, %

1 to 15

1 to 15

1 to 15

1 to 15

Compression set, %, max.

Under 0.110 inch (2.79 mm)

50

30

65

85

Over 0.110 inch (2.79 mm)

45

30

60

80

After aging 22 hours @ 75 ±5 °F (23.9 ±2.8 °C)

in AMS 2629, Type 1

Hardness change, points, max.

20

20

20

15

Tensile strength decrease, %, max.

50

45

30

35

Elongation decrease, %, max.

40

35

30

30

Volume change, %

1 to 25

1 to 25

1 to 25

1 to 25

1/ The permissible variation in specific gravity during actual production from that in first article tests shall be ±0.03.

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business