MIL-DTL-3533C

2.4 Order of precedence. Unless otherwise noted herein or in the contract, in the event of a

conflict between the text of this document and the references cited herein, the text of this

document takes precedence. Nothing in this document, however, supersedes applicable laws

and regulations unless a specific exemption has been obtained.

3. REQUIREMENTS

3.1 Material. Synthetic rubber furnished under this specification shall be a vulcanized

elastomeric compound which is resilient, oil and salt water resistant and shall not adhere to nor

cause corrosion of metal parts to which it is assembled.

3.2 Forms. Synthetic rubber shall be furnished in sheet, strip, cut or molded form as

specified (see 6.2).

3.2.1 Sheet and strip. Unless otherwise specified in the contract or order, the following

dimensions and tolerances shall apply. The width of sheet material shall be 36 inches plus or

minus 1 inch and the width of strip material as specified with tolerances of plus or minus 5

percent. The length shall have a tolerance of plus or minus 1 percent and tolerances on thickness

shall be as shown in Table I.

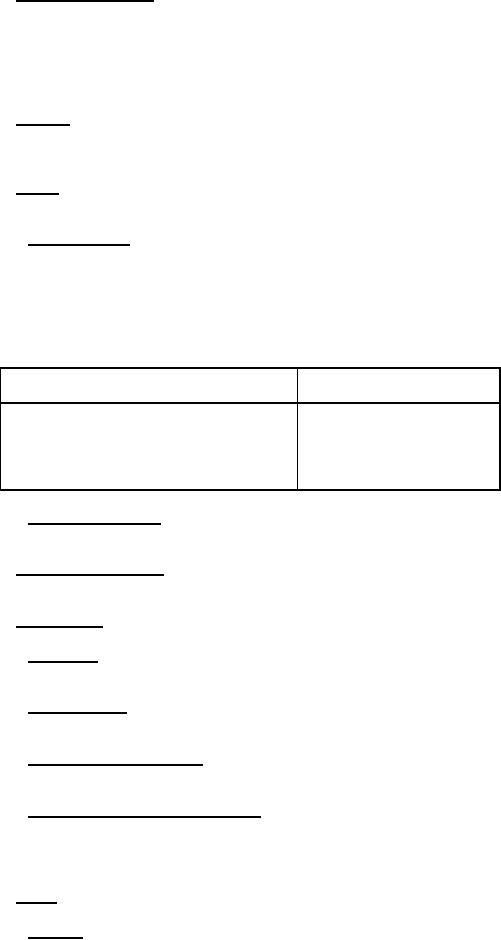

TABLE I. Tolerance in thickness

Thickness inch (mm)

Tolerance inch (mm)

Less than .0625 (1.59)

±.010 (.25)

.0625 (1.59) to .125 (3.18), inclusive

±.016 (.40)

Over .125 (3.18) to .500 (12.7), inclusive

±.031 (.80)

±.047 (1.20)

Over .500 (12.7) to 1.000 (25.4), inclusive

Over 1.000 (25.4)

±.063 (1.60)

3.2.2 Cut or molded parts. Shape, dimensions and tolerances shall be as specified on the

drawing or in the contract or order.

3.3 Physical requirements. The synthetic rubber material shall conform to the physical

requirements specified in Table II.

3.4 Performance.

3.4.1 Crush test. All O-Ring material when tested as specified in 4.4.4 shall be capable of

withstanding high compressive loadings without cracking or otherwise disintegrating.

3.4.2 Permanent set. When tested for permanent set as specified in 4.4.5, the samples shall

show no evidence of splitting or breaking.

3.4.3 Low temperature flexibility. Samples after being subjected to the test described in

4.4.7 shall show no visible signs of cracks, checks, or other damage.

3.4.4 Adhesion to and corrosion of metal. When tested in accordance with 4.4.8, the

specimens shall be readily separated from the metal with which they have been in close contact

and shall not cause corrosion pitting of such metal. A slight discoloration of the metallic contact

surfaces will be acceptable.

3.5 Finish.

3.5.1 General.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business