MIL-DTL-5521C

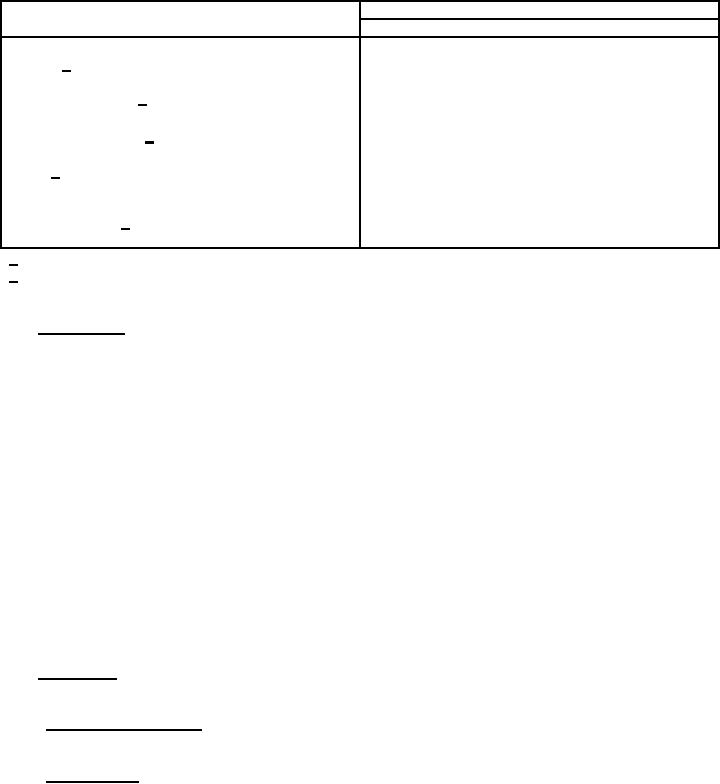

TABLE I

CHEMICAL COMPOSITION

Percent (by Weight)

Component

Minimum

Maximum

Grease 1/

3

8.0

Chlorides as NaCl 2/

--

.03

--

.03

Sulfates as H2SO4 2/

Shall be not more than 130 percent of the

Ash

2/

chromic oxide

3.5

--

Chromic oxide

2/

1/ Moisture-free basis.

2/ Moisture-free and grease-free basis.

3.8 Performance. The hydraulic back-up washers (the finished product) shall be subjected to tests in

Section 4 and shall conform to the requirements below:

a. Low temperature flexibility. There shall be no appreciable difference in the flexibility of the

washers at -54° Centigrade (C) ((-65° Fahrenheit (F)) and the flexibility of the washers at room

temperature (see 4.6.11).

b. Firmness. After being subjected to the firmness test, the washer cross section shall have

maintained a rectangular shape with the corners true and sharp, and sharp, and shall show no evidence

of flabbiness, peeling, disintegration, or malfunctioning (see 4.6.12).

c. Endurance. The Services reserve the right, when deemed necessary, to subject finished back-up

washers to endurance tests. Finished back-up washers, when installed in glands in accordance with MIL-

G-5514, shall be subjected to the applicable performance tests outlined in MIL-P-25732 except that the

operating pressure shall be 3000 psi (20.68 Mpa) (see 4.6.13).

d. Corrosion and adhesion. There shall be no corrosion and adhesion detected in the corrosion and

adhesion tests (see 4.6.14).

3.9 Dimensions. Finished hydraulic back-up washers shall conform to MS35803 or MS28777, as

applicable.

3.10 Identification of product. All hydraulic packing back-up washers shall be identified by a dye applied

to the hair side of the hide. The color of the dye shall be specified by the procuring activity.

3.11 Workmanship. All details of workmanship shall be in accordance with high grade commercial

practice.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business