MIL-PRF-17927D

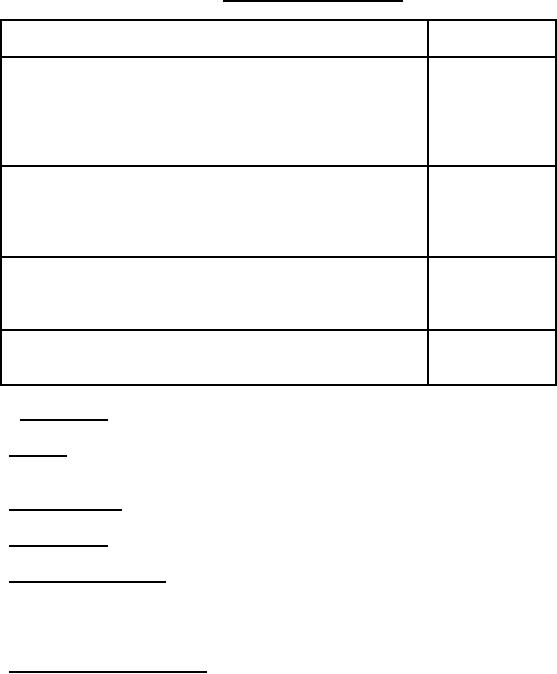

TABLE I. Physical properties of rubber.

Properties

Values

Initial Properties

Hardness, durometer points, ±5

30

Tensile strength, (min), pounds per square inch (PSI)

1450

Ultimate elongation (min), %

500

Compression set, max, %, 22h at 350 ºF

35

Oil immersion, No. 3 oil, 22h at 350 ºF, max volume change, %

+80

Heat Resistance

Change in hardness max, points

±10

Change in tensile strength max, %

-50

Change in elongation max, %

-50

Water Resistance

Change in hardness, points

±5

Change in volume, %

±5

Tear Resistance

1015 to 1500 PSI load, min, pound force per inch (lbf/in)

143

3.2.2 Outer layer(s). The outer layer(s) shall protect the core.

3.3 Adhesion. The outer layer(s) shall adhere to the core such that stripping the outer layer(s) from the

core causes cohesive failure.

3.4 Sealing durometer. The sealing durometer of the finished gasket shall be as specified in Table II.

3.5 Tensile strength. The gasket shall have a minimum tensile strength of 300 pounds per inch.

3.6 Flame and heat resistance. The finished gasket shall show no melting or loss of material when

subjected to the heat test of 4.4.6. When subjected to the flame test of 4.4.6, the gasket shall burn for not more

than 60 seconds. The outer covering shall hold its shape and texture when the gasket is subjected to the flame

and heat tests .

3.7 Dimensions, tolerances and size. The dimensions for the finished gasket shall be as shown in Table II.

The finished gasket shall be within a tolerance of plus 1/16 inch, minus 0 inch. No minus tolerance shall be

permitted.

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business