MIL-PRF-17927D

b. Conformance inspection (see 4.3).

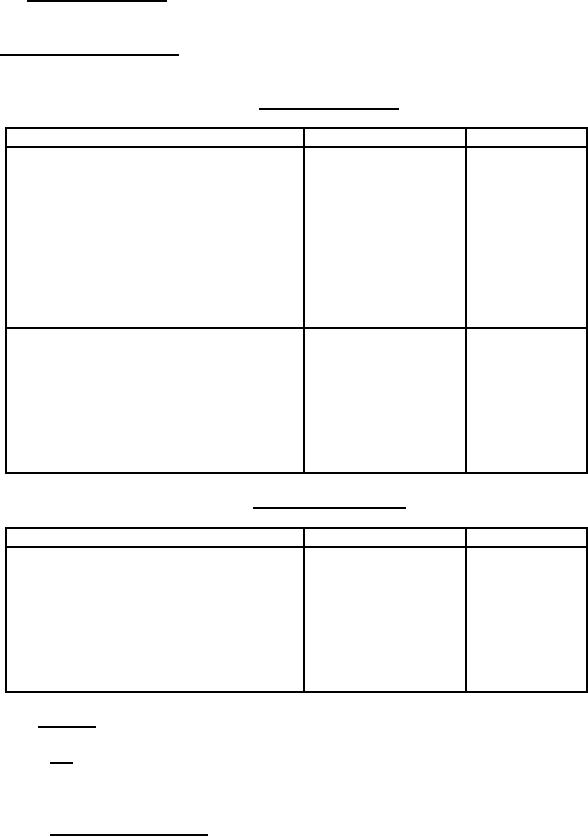

4.2 First article inspection. First article inspection shall consist of the examinations and the tests

specified in Table III.

4.3 Conformance inspection. The conformance inspection shall consist of the examinations and

tests as specified in Table IV.

Table III. First article inspection.

Examinations, Measurements and Test

Requirements

Test

Performed on Core

Hardness

3.2.1

4.4.2

Tensile strength and elongation

3.2.1

4.4.2

Comparison set

3.2.1

4.4.2

Oil immersion (volume change)

3.2.1

4.4.2

Heat resistance

3.2.1

4.4.2

Water resistance

3.2.1

4.4.2

Tear resistance

3.2.1

4.4.2

Performed on Finished Gasket

Adhesion

3.3

4.4.3

Sealing durometer

3.4

4.4.4

Tensile strength

3.5

4.4.5

Flame and heat resistance

3.6

4.4.6

Dimensions, tolerances and size

3.7

-

Toxicity

3.9

4.4.7

Table IV. Conformance inspection.

Examinations, Measurements and Test

Requirements

Test

Performed on Finished Gasket

Adhesion

3.3

4.4.3

Sealing durometer

3.4

4.4.4

Tensile strength

3.5

4.4.5

Flame and heat resistance

3.6

4.4.6

Dimensions

3.7

4.3.1 Sampling.

4.3.1.1 Lot. For the purposes of sampling, examination, and tests, a lot shall consist of all gaskets of the

same size, produced in one plant under essentially the same conditions, not exceeding 2500 feet and offered for

delivery at one time.

4.3.1.2 Sampling for examination. As specified in 4.3.3, a random sample of reels shall be selected

from each lot of gasket material for examination. Examination shall be in accordance with inspection level II of

ASQC Z1.4.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business