MIL-DTL-22050E (SH)

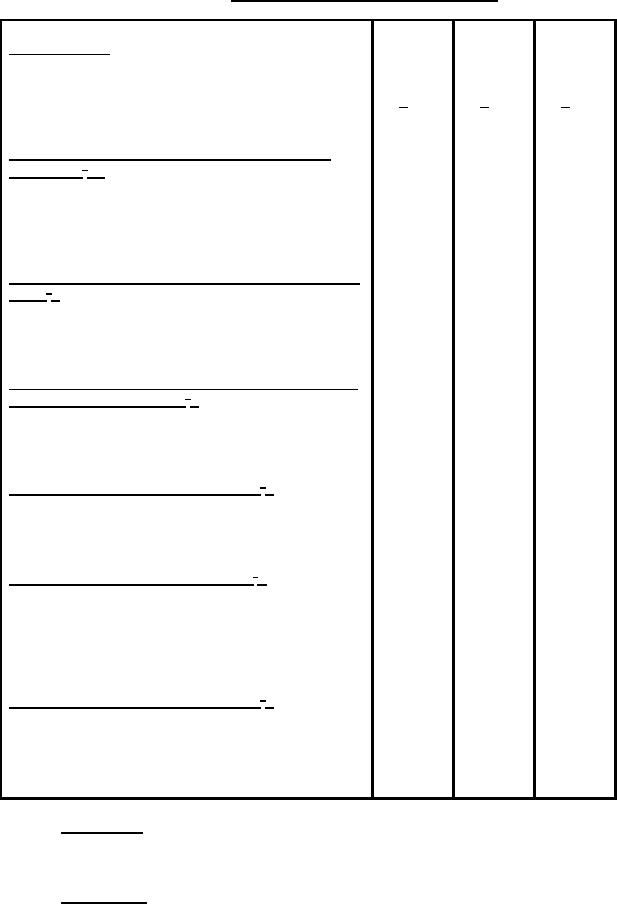

TABLE I. Physical requirements of rubber compounds.

Grade 1

Grade 2

Grade 3

Initial properties:

Tensile strength, psi, minimum (min)

2400

2400

2200

Ultimate elongation, percent, min.

250

150

80

Hardness, Shore A durometer, points within 1 sec

65 + 5

80 + 5

90 + 5

Leachable chlorides (parts per million) maximum (max)

200

200

200

Properties after oven aging 166 Hours at 280 degrees

Fahrenheit (o F)

Tensile strength, percent of initial, min.

70

70

70

Ultimate elongation, percent of initial, min.

70

70

50

Hardness, change in Shore A durometer, points max.

15

15

15

Compression set, percent, max.

60

60

35

Properties after immersion in distilled water for 166 hours

at 330oF:

Tensile strength, percent of initial, min.

80

80

80

Ultimate elongation, percent of initial, min.

80

80

80

Volume change, percent (no shrinkage allowed)

0 to 10

0 to 10

0 to 10

Properties after immersion in 25 percent aqueous solution

of MEA for 166 hours at 330oF:

Tensile strength , percent of initial, min.

80

80

--

Ultimate elongation, percent of initial, min.

80

80

--

Volume change, percent (no shrinkage allowed)

0 to 10

0 to 10

--

Properties after 166 hours in steam at 330oF:

Tensile strength, percent of initial, min.

80

80

80

Ultimate elongation, percent of initial, min.

80

80

80

Volume change, percent, max.

5

5

5

Properties after 70 hours in steam at 390oF:

Tensile strength, percent of initial, min.

--

--

90

Ultimate elongation, percent of initial, min.

--

--

85

Hardness, change in Shore A durometer, points max.

--

--

3

Volume change, percent (no shrinkage allowed)

--

--

0 to 8

Compression set, percent, max.

--

--

60

Properties after 166 hours in steam at 550oF:

Tensile strength, percent of initial, min.

--

--

75

Ultimate elongation, percent of initial, min.

--

--

15

Hardness, change in Shore A durometer, points max.

--

--

10

Volume change, percent (no shrinkage allowed)

--

--

0 to 5

Compression set, percent, max.

--

--

90

3.4 Identification. Material acquired under this specification shall be identified with white markings. A

permanent marking material that will have no deleterious effect on the rubber shall be used or in the case of

individual one-item packaging, the marking may be put on the package.

3.5 Workmanship. The material shall be examined for defects as specified herein.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business