MIL-DTL-22050E (SH)

3.6 Recycled, recovered, or environmentally preferable materials. Recycled, recovered, or

environmentally preferable materials should be used to the maximum extent possible provided that the material

meets or exceeds the operational and maintenance requirements, and promotes economically advantageous life cycle

costs.

3.7 Toxicity. When evaluated in accordance with 4.5, the gasket and packing material shall have no

adverse effect on the health of personnel when used for its intended purpose and shall not cause any environmental

problems during waste disposal (see 4.5 and 6.6).

3.8 Disposal. The manufacturer shall certify that the gasket and packing material shall not contain any

hazardous material or exhibit any hazardous characteristic as defined under 40 CFR 261 (Code of Federal

Regulations). The manufacturer shall make every effort to adhere to this requirement. If no product which meets

this requirement can be identified, (i.e., if the gasket and packing material does contain a hazardous material), the

manufacturer shall provide information detailing proper disposal of the gasket and packing material.

3.9 Off-gassing. The gasket and packing material shall meet the requirements in the Nuclear Powered

Submarine Atmosphere Control Manual, NAVSEA Technical Manual S9510-AB-ATM-010 Rev 2, for a usage

category of Limited (see 4.6 and 6.7).

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified as follows:

a. Conformance inspection (see 4.2)

4.2 Conformance inspection. Conformance inspection shall consist of the examinations and tests specified

in 4.3.

4.2.1 Lot. For the purpose of conformance inspection and testing, a lot is defined as all the material

produced in one facility, using the same materials, of the same grade, using the same production processes, not

exceeding 1000 pounds, and being offered for delivery at one time.

4.2.2 Sampling for conformance inspection. As a minimum, the contractor shall randomly select a sample

quantity of test specimens as defined in 4.2.3 from each lot of completed material in accordance with Table II and

inspect them in accordance with the examinations and test specified herein. If one or more defects are found in any

sample, the entire lot shall be rejected. The contractor has the option of screening 100 percent of the rejected lot for

the defective characteristic(s) or providing a new lot which shall be inspected in accordance with the sampling plan

contained herein. The contractor shall maintain for a period of three years after contract completion records of

inspections, tests, and any resulting rejections.

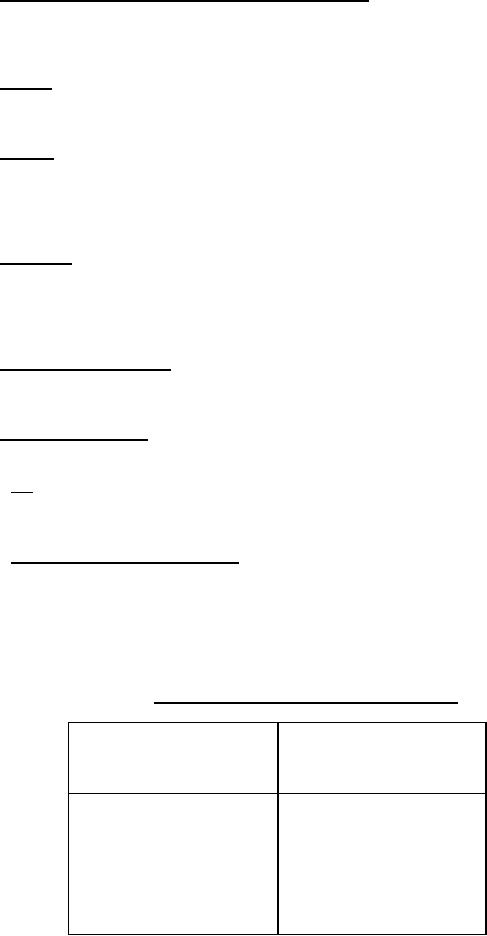

TABLE II. Sample size for conformance inspections and tests.

Lot size

Sample size

number of gaskets, molded

number of gaskets, molded

items, packings, or unit areas of

items, packings, or unit areas

sheets or strips

of sheet or strips

2 to 50

5

51 to 90

7

91 to 150

11

151 to 280

13

281 to 500

16

501 to 1200

19

1201 to 3200

23

3201 and over

29

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business