MIL-PRF-2765E

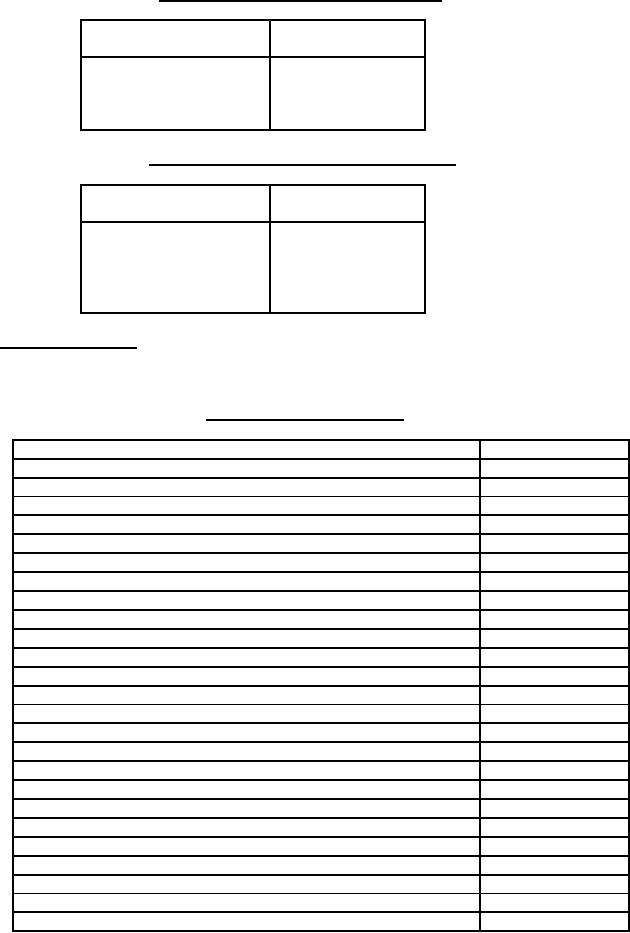

TABLE I. Tolerance in width for sheet and strip material.

Width

Tolerance

(plus or minus)

1/4 to 1/2 inch

1/32 inch

Over 1/2 to 1 inch

3/64 inch

Over 1 to 2 inches

1/16 inch

Over 2 inches

3 percent

TABLE II. Tolerance in thickness for sheet and strip material.

Thickness - inch

Tolerance - inch

(plus or minus)

Less than 1/16

0.010

1/16 to 1/8

1/64

Over 1/8 to 1/2

1/32

Over 1/2 to 1

3/64

Over 1

1/16

3.4 Physical requirements. The synthetic rubber material shall conform to the requirements specified in

Table III.

TABLE III. Physical requirements of rubber.

Initial properties

Requirement

2

Tensile strength, 1b/in minimum

1000

Ultimate elongation, percent, minimum

300

Hardness, Type A durometer

35 to 55

Specific gravity, maximum

1.65

Delamination, after liquid immersion

No delamination

Properties after oven aging

Tensile strength, percent of initial, minimum

80

Ultimate elongation, percent of initial, minimum

70

Hardness, Type A durometer, maximum

60

Hot compression set, percent, maximum

40

Properties after oil-immersion

Tensile strength, 1b/in2 minimum

1000

Ultimate elongation, percent, minimum

300

Volume change, percent, maximum (no shrinkage allowed)

plus 25

Low temperature properties

Hardness Type A durometer, maximum

60

Cold compression set, before and after oil immersion

Percent, maximum, 10 seconds after release

75

Percent, maximum, 30 minutes after release

35

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business