MIL-DTL-5516D

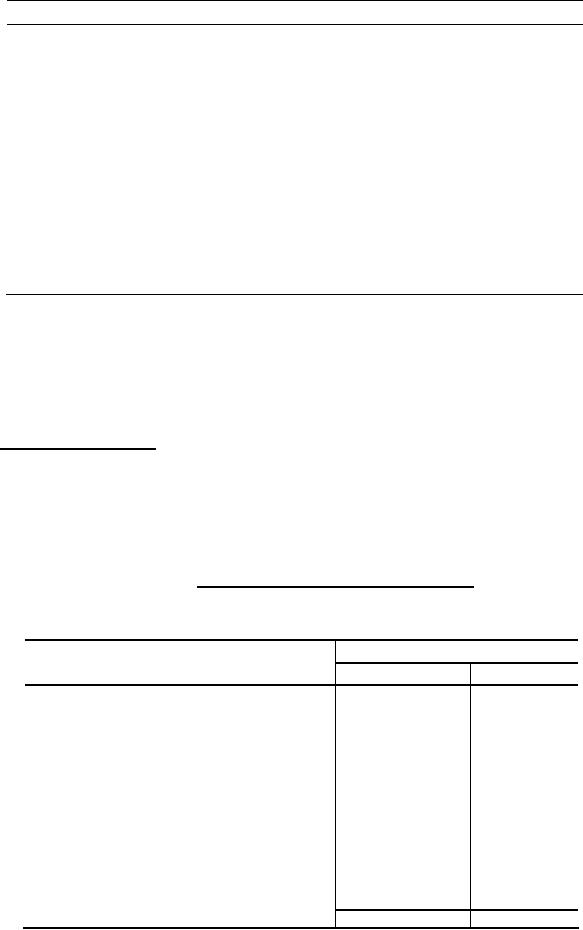

TABLE II. Maximum production permissible variations in physical properties from

contractors' first article values.

Property

Class A

±0.021

Specific gravity, points

Hardness, shore A durometer at

±3 2

24° ± 3°C. (75° ± 5°F), points

Tensile strength, percent

±15

Elongation, percent

±20

Modulus, pounds, percent

Not required

Permanent set, percent

±20

Corrosion and adhesion

Slight corrosion on steel

Volume change

Swell determined from first article

test value ±2 (see example 3) but

must stay within limits specified in

Table I.

1

If basic specific gravity is 1.30, then limits can be 1.28 to 1.32.

2

Shore hardness on production samples shall be not less than 85 for class A material with

this tolerance applied.

3

Example: If first article swell of V-ring is +1 percent, then limits can be 0 to 3 percent; if

+5 percent, then limits can be 3 to 7 percent; or if +8 percent, then limits cxan be 6 to 10

percent.

3.8 Identification of product. The following general marking shall be used, unless otherwise

specified by the procuring activity.

3.8.1 V-ring packings shall have the manufacturer's trademark and the applicable size dash

number molded into the surface of the inner Vee close to the apex of the angle. If any other

marking is used, it shall be specially approved by the procuring activity. If raised figures are used,

the height shall not exceed 0.010 inch (.254mm).

Table III. - Test samples required for First Article tests

Physical Property Test

AN6225 V-ring

Tests

-20

-25

Unaged samples (table I):

Specific gravity

Tensile strength and elongation

Tensile stress (modulus)

Permanent set

Corrosion and adhesion

5

Air-aged (table I):

Tensile strength and elongation

Permanent set

Oil-aged (table I):

Tensile strength and elongation

Permanent set

Volumetric change

6

6

Subtotal (physical)

11

6

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business