MIL-DTL-81716A

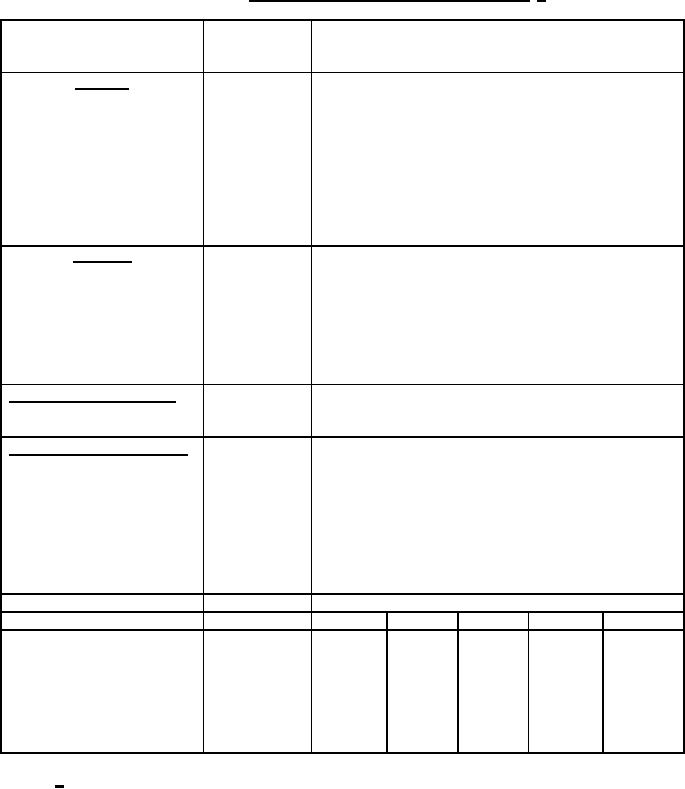

TABLE I. First Article Inspection Tests and Samples 1/

Physical Property

Paragraph

Specimen

Tests

Number

Unaged

Hardness

4.5.2.1

1 ASTM Hardness disc (.250 in. (6.35 mm) thick

x 1. 0 in. (25.4 mm) diameter)

Tensile strength

4.5.2.2

2 SAE AS33931, MS3393-16

Elongation

2 SAE AS33931, MS3393-16

4.5.2.3

Specific gravity

3 SAE AS33931, MS3393-16

4.5.2.4

Permanent set

4.5.2.5

2 SAE AS33931, MS3393-3

Temperature retraction

4.5.2.6

3 SAE AS33931, MS3393-16

Corrosion & adhesion

4.5.2.8

12 SAE AS33931, MS3393-16

Air Aged

Hardness

4.5.2.1

1 ASTM Hardness disc (.250 in. (6.35 mm) thick

x 1. 0 in. (25.4 mm) diameter)

Tensile strength

4.5.2.2

2 SAE AS33931, MS3393-16

Elongation

4.5.2.3

2 SAE AS33931, MS3393-16

Permanent set

4.5.2.5

2 SAE AS33931, MS3393-3

Oil Aged at 158F (70°C)

4.5.2.6

3 SAE AS33931, MS3393-16

Temperature retraction

Oil Aged at 275 F (135°C)

1 ASTM Hardness disc (.250 in. (6.35 mm) thick

4.5.2.1

Hardness

x 1. 0 in. (25.4 mm) diameter)

2 SAE AS33931, MS3393-16

4.5.2.2

Tensile strength

4.5.2.3

2 SAE AS33931, MS3393-16

Elongation

4.5.2.5

2 SAE AS33931, MS3393-3

Permanent set

4.5.2.7

3 SAE AS33931, MS3393-16

Volume change

Performance Tests

SAE AS33931, MS3393 Packing

-3 Size

-4 Size

-8 Size -12 Size

-16 Size

Installation stretch at

12

4.5.2.9.1

normal temperature

Installation stretch at

-20F (-29°C)

6

4.5.2.9.2

9

4.5.2.10

Crush

9

4.5.2.11

Extrusion

4

4.5.2.12

4

4

4

Impulse

1/ All SAE AS33931, MS3393 packings shall be examined in accordance with 4.5.1 before

the initiation of first article tests.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business