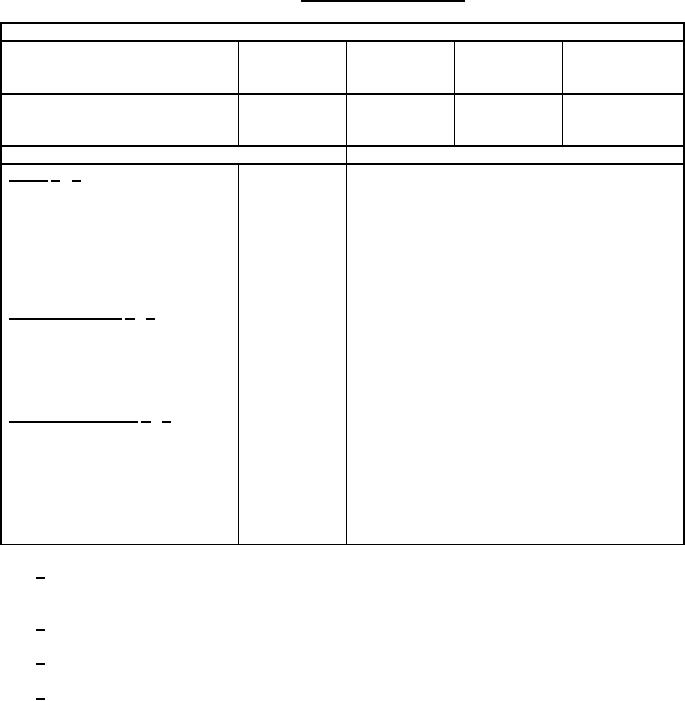

MIL-DTL-81716A

TABLE II. Conformance Inspection

(all specimens unaged except Volume change)

AQL

Paragraph

Sampling

Inspection

(percent

Inspection

Number

plan per

level

defective)

Examination of product

4.5.1

ASQ Z1.4

S-4

4.0

Examination of preparation for

4.5.1.1

ASQ Z1.4

S-4

6.5

delivery

Specimen

Batch 1/, 2/

1 ASTM Hardness disc (.250 in. (6.35 mm)

4.5.3.1

(a) Hardness

thick x 1. 0 in. (25.4 mm) diameter)

4.5.3.2

2 SAE AS33931, MS3393-16 packings

(b) Tensile strength

4.5.3.3

2 SAE AS33931, MS3393-16 packings

(c) Elongation

3 SAE AS33931, MS3393-16 packings

4.5.3.4

(d) Specific gravity

Finished Product 2/, 3/

2 SAE AS33931, MS3393-16 packings

(a) Tensile strength

4.5.3.2

2 SAE AS33931, MS3393-16 packings

(b) Elongation

4.5.3.3

3 SAE AS33931, MS3393-16 packings

(c) Specific gravity

4.5.3.4

Process monitoring 2/, 4/

2

SAE AS33931, MS3393-3 packings

(a) Permanent set

4,5.3.5

3

SAE AS33931, MS3393-16 packings

(b) Temperature retraction

4.5.3.6

3

SAE AS33931, MS3393-16 packings

(c) Volume change

4.5.3.7

12

SAE AS33931, MS3393-16 packings

4.5.3.8

(d) Corrosion and adhesion

3

SAE AS33931, MS3393-16 packings

(e) Crush

4.5.2.10

1/ A batch shall consist of the quantity of material compounded at any one time and ready for

molding and curing into a fished product. Test specimen shall be molded from each batch

and finished with the same state of cure as the finished product.

2/ If a test specimen or sample fails to pass any of these tests, the lot or batch represented

by the unit shall be rejected.

3/ Finished product tests shall be performed on unaged specimens or samples from each

day's production molded concurrently with other production parts.

4/ Process monitoring test shall be performed at 3 month intervals on unaged specimen

molded concurrently with production parts, and using the same production techniques.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business