MIL-PRF-15624G

APPENDIX A

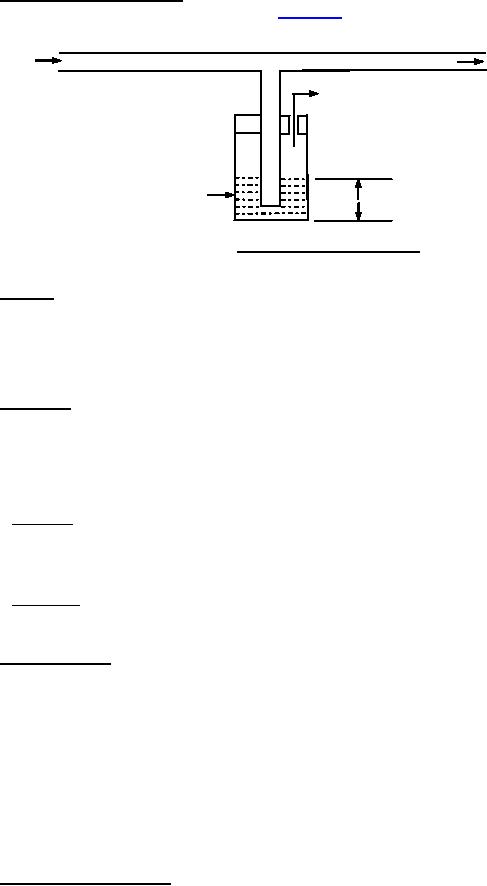

A.2.5 Initial leakage point apparatus. An apparatus to determine the initial leakage point of the specimen shall

consist of a 1 psi (7 kPa) air supply such as illustrated on figure A-4, which can be taken from the main air supply.

AIR

TO JIG

VENT

MERCURY

2"

FIGURE A-4. Initial leakage point apparatus.

A.2.6 Air oven. A conditioning air oven capable of maintaining the specified temperature and of sufficient size

to hold the indenting device will be required. The air oven shall be provided with proper temperature control to

maintain the specified temperature within a permissible variation of ±3.6 °F (±2 °C). Satisfactory circulation of the

air shall be secured by means of a fan.

A.3 TEST SPECIMEN

A.3.1 Preparation. The test specimen shall be a cylindrical disk 0.485±0.015 inch (12.5±0.5 mm) in thickness,

cut from the vulcanized rubber part or from a test sample if the part is unsuitable. A sharp, circular die having an

inside diameter of 1.129±0.001 inch (28.68±0.02 mm) shall be used. In cutting the specimen, the die shall be

suitably rotated in a drill press or similar device and lubricated by means of soapy water, so that a smooth cut

surface having square edges is obtained. The cutting pressure shall be kept sufficiently small to avoid "cupping" of

the cut surface.

A.3.1.1 Thickness. When necessary, the specimen thickness shall be reduced to the required thickness by

cutting with a sharp knife and carefully buffing to size within the permissible tolerance. The buffing shall be done

lightly to avoid overheating and care shall be taken to keep the circular faces parallel and at right angles to the axis

of the cylinder.

A.3.1.2 Combining. If necessary, the test specimen may be made of two pieces essentially equal in thickness.

A.4 PROCEDURE FOR INITIAL PRESSURE SEALING

A.4.1 Zero sealing point.

a.

Make the zero point measurement after inserting the test specimen all the way into the specimen holder and

placing the latter in the indenting device.

b.

Adjust the indenting device until the test specimen just contacts the indentor.

c.

Cover the surface of the specimen with water or alcohol, and connect the indentor to the 1 psi (7 kPa) air

supply.

d.

Further adjust the indenting device until the initial leakage point is that point at which a leakage occurs at a

rate of one bubble in 10 seconds at 1 psi (7 kPa) air pressure. Record the initial indentation reading.

e.

Back the indentor off and repeat the procedure. If a second adjustment falls within 0.01 mm (0.0005 inch) of

the first, it shall be considered satisfactory. If not, repeat the operation until two successive adjustments

check within 0.01 mm (0.005 inch).

A.4.2 Indentation of test specimen. Indent the test specimen to 0.0625±0.0005 inch (1.59±0.01 mm), by

adjusting the indenting device. After the indentation, allow the specimen to rest for 30 minutes prior to the

determination of the initial sealing pressure.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business