MIL-PRF-15624G

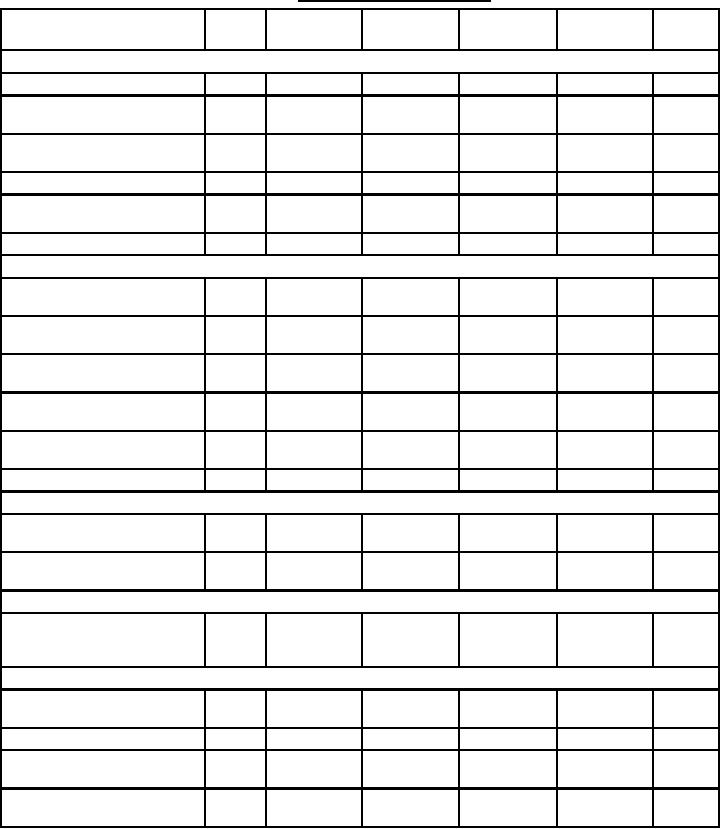

TABLE II. Physical requirements of rubber.

First

Test

Material Condition

Conformance

Class I

Class II

Class III

Article

Method

Initial properties:

Tensile strength, psi, minimum

X

X

1500

1000

1500

Ultimate elongation, percent,

X

X

400

300

400

minimum

Hardness, durometer points,

X

X

50

50

50

maximum

Specific gravity, maximum

X

X

1.60

1.40

1.40

Tensile stress (modulus) psi at

X

X

As determined

As determined

As determined

100% elongation

Sealing pressure, psi, minimum

X

95

95

95

Properties after oven aging:

Tensile strength, percent of initial,

X

75

75

75

minimum

Ultimate elongation, percent of

X

70

70

70

initial, minimum

Hardness, durometer points,

X

65

65

65

maximum

Tensile stress (modulus) psi at

X

As determined

As determined

As determined

100% elongation

Compression set, percent,

X

30

30

30

maximum

Sealing pressure, psi, minimum

X

70

70

70

Properties after light aging:

Tensile strength, percent of initial,

X

75

75

75

minimum

Ultimate elongation, percent of

X

70

70

70

initial, minimum

Properties after low temperature aging:

No cracks,

No cracks,

No cracks,

Flexibility

X

tears, or

tears, or

tears, or

separation

separation

separation

Properties after liquid immersions:

Volume change, after water

X

0 to 5

N/A

N/A

immersion, percent

Extraction, percent, maximum

X

0.5

N/A

N/A

Volume change, after immersion

X

0 to 10

N/A

N/A

in ASTM No. 1 oil, percent

Volume change, after immersion

X

N/A

N/A

0 to 30

in Reference Fuel B, percent

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business