MIL-PRF-24790A (SH)

3. REQUIREMENTS

3.1 Qualification. Packing material furnished under this specification shall be products that are authorized

by the qualifying activity for listing on the applicable qualified products list before contract award (see 4.3 and

6.3).

3.2 Material.

3.2.1 Composition. The packing material ingredients, shape and construction shall conform to that of the

sample submitted for qualification inspection. For braided packing, except for 1/8-inch and 3/16-inch sizes, the

material shall be braided to a diagonal interlocking through body-to-surface construction (as opposed to braid-over-

braid or square-braid construction) to product a dense packing with good dimensional stability. The 1/8-inch and

3/16-inch braided packings shall be square plait-braided.

3.2.2 Recycled, recovered, or environmentally preferable materials. Recycled, recovered, or environmentally

preferable materials should be used to the maximum extent possible provided that the material meets or exceeds

the operational and maintenance requirements, and promotes economically advantageous life cycle costs.

3.3 Performance characteristics.

3.3.1 Flexibility. The packing shall be flexible enough to be formed readily into coils to fit a rod with a

diameter which is equal to five times the size of the packing. Any sign of voids or separations between the rod and

the packing shall be cause for disqualification (see 4.6.1 and 6.7).

3.3.2 Packing and fluid compatibility. To qualify for each specific type and class (see 1.2), the packing

material shall be immersed in the fluids specified in table I and shall meet the requirements of 3.3.2.1 through

3.3.2.3.

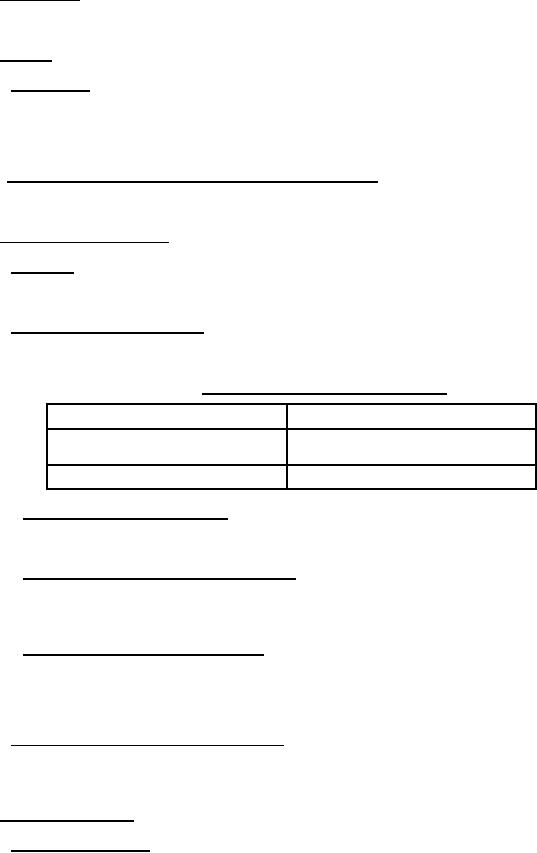

TABLE I. Immersion fluids for compatibility tests.

Type

Fluid

Fresh water and Seawater, and

Type I, Class A

Boiler feedwater

Type II, Class A

Fresh water

3.3.2.1 Flexibility and fluid compatibility. Fluid media effect on flexibility shall be determined after fluid

immersion (see 4.6.2.1). Any signs of voids or separations between the rod and the packing shall be cause for

disqualification of a material for the class that includes the fluid which caused the change.

3.3.2.2 Dimensional stability and fluid compatibility. Fluid media effect on dimensional stability shall be

determined by comparing cross-sectional dimensions of a sample of 1/2-inch square packing after fluid immersion

with packing dimensions before immersion (see 4.6.2.2). A 5 percent or greater change from the original

dimensions shall be cause for disqualification of a material for use in the fluid which caused the change.

3.3.2.3 Tensile strength and fluid compatibility. Fluid media effect on tensile strength shall be determined

by comparing tensile strength measurements before and after fluid immersion (see 4.6.2.3). Post immersion tensile

strength measurements shall be no less than 95 percent of pre-immersion tensile strength measurements. A tensile

strength which is less than 95 percent of the tensile strength of the reference (pre-immersion) material shall be

cause for disqualification of material for use in the fluid which caused the change.

3.3.3 Thermogravimetric analyzer (TGA) analysis. Thermogravimetric analyses shall be conducted to

determine weight loss as a function of heat. Material weight loss as a function of heat shall be recorded and

compared with original (pre-heating) material measurements. If weight loss exceeds 10 percent at a temperature

which is less than the applicable temperature specified in 1.2, the material shall be disqualified (see 4.6.3).

3.4 Detrimental materials.

3.4.1 Halogen concentration. Packing materials, Type I, Class A and Type II, Class A, shall be tested for

halogen concentration (that is, the sum of total bromide, total chloride, and total fluoride ions) (see 4.6.4.1). The

following limits shall apply:

(a)

Either total halogens shall not exceed 250 parts per million (ppm), or

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business