MIL-PRF-24790A (SH)

(b)

Halogen concentration excluding fluoride shall not exceed 250 ppm and the packing manufacturer shall

certify in writing that: "the only intentionally added, fluoride-bearing ingredient is

polytetrafluoroethylene," or

(c)

The sum of water-leachable halogens shall be less than 250 ppm when tested as specified in 4.6.4.1.1.

3.4.2 Total sulfur concentration. Packing materials, Type I, Class A, and Type II, Class A, shall be tested for

total sulfur concentration which shall not exceed 700 ppm unless otherwise approved by NAVSEA when tested as

specified in 4.6.4.2.

3.4.3 Mercury. During manufacturing, fabrication, handling and packaging, the pump packing (all types

and classes) shall not come into contact with mercury or mercury compounds.

3.4.4 Other detrimental materials. For packing materials, Type I, Class A, and Type II, Class A, the

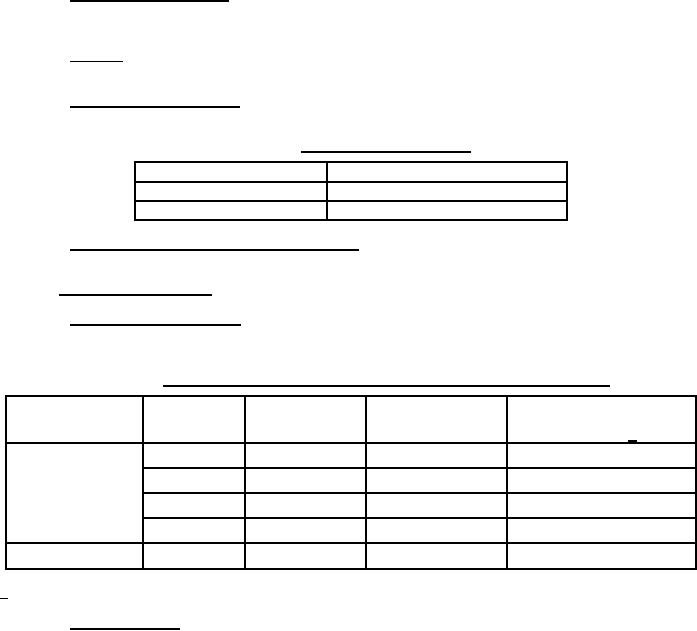

maximum concentrations specified in table II also apply (see 4.6.4.3).

TABLE II. Other detrimental materials.

Material

Max concentration (ppm)

Cadmium

250

Lead

250

3.4.5 Asbestos and polychlorinated biphenyls (PCBs). No asbestos or PCBs shall be used in the packing

material (all types and classes) (see 6.3).

3.5 Simulated service testing. Packing materials shall be tested as specified in 4.6.5.

3.5.1 Packing gland leakage rates. Maximum allowable value of the average overall leakage rates during

simulated service testing of rotary and reciprocating pump packings shall be as specified in table III (see 4.6.5 and

6.6).

TABLE III. Maximum allowable value of average overall packing gland leakage rates.

Maximum allowable value

Type/class

No. packing

Shaft speed

Fluid media

of average overall leakage

packing

rings

(fpm.)

rate (max) 1/

Type I, Class A

5

4000

Fresh water

300 mL/min.

4

2100

Fresh water

60 mL/min.

4

1700

Seawater

411 mL/min.

5

5400

Boiler feedwater

945 mL/min.

Type II, Class A

5

170

Sat. L.P. stm.

300 mL/min.

1/ Milliliters per minute (mL/min).

3.5.2 Shaft temperature. During the simulated service testing of Type I, Class A packings (freshwater and

boiler feedwater only), the shaft temperature as measured by the resistance temperature device (RTD) shall meet

the following criteria:

(a)

High speed fresh water (4000 fpm) rotary pump packings.

(1)

The shaft temperature shall not exceed 570 ºF.

(2)

The shaft temperature shall be not greater than 270 ºF for a continuous period of 5 minutes or

more.

(3)

The average overall shaft temperature shall not exceed 260 ºF (see 6.6).

(b)

Low speed fresh water (2100 fpm) rotary pump packings.

(1)

The shaft temperature shall not exceed 570 ºF.

(2)

The shaft temperature shall be not greater than 250 ºF for a continuous period of 15 minutes or

more.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business