MIL-PRF-24790A (SH)

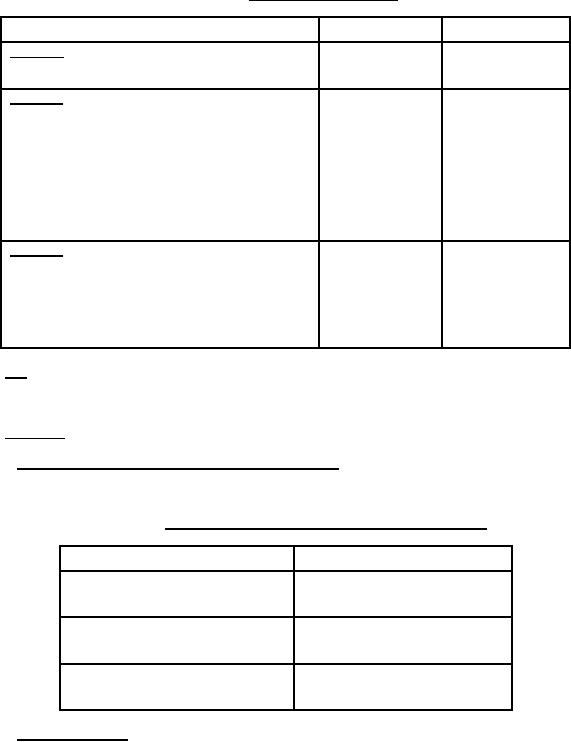

TABLE VI. Conformance inspection.

Inspection

Requirement

Test method

Group A

Workmanship

3.8

4.5.1.1

Dimensions

3.6

4.5.1.1

Group B

Flexibility

3.3.1

4.6.1

Fluid compatibility

3.3.2

4.6.2

Flexibility

3.3.2.1

4.6.2.1

Dimensional stability

3.3.2.2

4.6.2.2

Tensile strength

3.3.2.3

4.6.2.3

TGA analysis

3.3.3

4.6.3

Halogen concentration

3.4.1

4.6.4.1

Total sulfur concentration

3.4.2

4.6.4.2

Other detrimental materials

3.4.4

4.6.4.3

Group C

Simulated service testing

3.5

4.6.5

Packing gland leakage rates

3.5.1

4.6.5

Shaft temperature

3.5.2

4.6.5

Shaft wear

3.5.3

4.6.5.1

Fixture cavity residue

3.5.4

4.6.5

Replacement of packing rings

3.5.6

4.6.5

4.4.1 Lot. For purposes of quality conformance and test sampling, a lot is defined as all finished packing of

one class, type and size, produced in one facility, using the same production processes and materials, and being

offered for delivery at one time.

4.4.2 Sampling.

4.4.2.1 Sampling for visual examination of packing material. At a minimum, the contractor shall randomly

select samples from each lot of completed spools or reels of packing as specified in table VII, and inspect them as

specified in 4.5.1.1 (see 6.7).

TABLE VII. Sampling for visual examination of packing material.

Lot size

Sample size

2 to 50

5

7

51 to 90

91 to 150

11

151 to 280

13

281 to 500

16

501 to 1,200

19

1,201 to 3,200

23

3,201 to 10,000

29

10,001 to 35,000

35

4.4.2.2 Sampling for tests. At a minimum, the contractor shall randomly select a sample quantity from each

lot of completed spools or reels of packing as specified in table VIII, and test them as specified in 4.6.1 through

4.6.5 (see 6.7).

7

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business