MIL-PRF-24790A (SH)

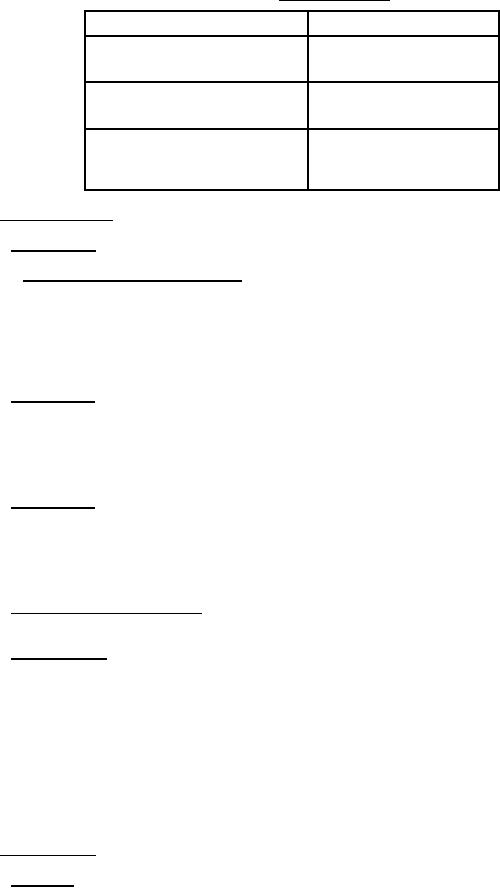

TABLE VIII. Sampling for tests.

Lot size

Sample size

2 to 25

3

26 to 50

5

51 to 90

6

91 to 150

7

151 to 280

10

281 to 500

11

501 to 1,201

15

1,201 to 3,200

18

3,201 to 10,000

22

10,001 to 35,000

29

4.5 Conformance tests.

4.5.1 Group A tests. Group A tests shall be performed for all conformance inspections (see 4.5.1.1).

4.5.1.1 Visual examination and dimensions. Packing material shall be carefully examined by visual

inspection to detect defects in workmanship and dimensions (see 3.8). For each spool or reel of packing material,

major defects such as a rip, tear, hole, void, crease, crimp, gouge, or extraneous particulate matter on the surface,

shall be cause for rejection of that spool or reel. Minor surface defects not affecting the serviceability of the

packing material shall not be cause for rejection. Cross-sectional dimensions shall be measured at no less than

two-foot intervals along the length of two adjacent sides of the spool or reel, using a metal ruler graduated to 1/64-

inch (see 3.6).

4.5.2 Group B tests. Group B tests shall be omitted if both of the following are true:

(a)

Within 2 years preceding the date current lot will be delivered by the contractor, the material has been

tested and found in conformance with the group B requirements of table VI.

(b)

The material offered for delivery is manufactured the same in all respects as the sample submitted that

qualified the material.

4.5.3 Group C tests. Group C tests shall be omitted if both the following are true:

(a)

Within 3 years preceding the date current lot will be delivered by the contractor, the material has been

tested and found in conformance with the group C requirements of table VI.

(b)

The material offered for delivery is manufactured the same in all respects as the sample submitted that

qualified the material.

4.5.4 Composition or process change. Any changes in composition or process shall be promptly reported to

the contracting activity.

4.5.5 Noncompliance. If a sample fails to pass any of the inspections in groups B and C, the contractor shall

notify the contracting activity and the cognizant inspection activity of such failure and take corrective action on the

materials or processes, or both, as warranted, as well as on all units of product which can be corrected and which

are manufactured under essentially the same materials and processes, and which are considered by the qualifying

activity to be subject to the same failure. Acceptance and shipment of the product shall be discontinued until

corrective action, acceptable to the contracting activity, has been taken. After the corrective action has been taken,

all of the inspections in groups B and C shall be repeated on additional sample units (this includes all tests and

examinations, or the test which the original sample failed, at the option of the contracting activity). Group A

inspections may be performed again, but final acceptance and shipment shall be withheld until group B and C

inspections have shown that the corrective action was successful. In the event of failure after reinspection,

information concerning the failure shall be furnished to the cognizant inspection activity and to the contracting

activity.

4.6 Test procedures.

4.6.1 Flexibility. The packing shall be coiled by hand around a rod with a diameter which is equal to or less

than five times the size of the packing. A visual examination shall then be made to determine whether the packing

conforms to the curvature of the rod with no voids or separation between the packing and the rod (see 3.3.1).

8

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business