MIL-PRF-24790A (SH)

(3)

The shaft temperature shall be not greater than 275 ºF for a continuous period of 2 minutes or

more.

(4)

The average overall shaft temperature shall not exceed 250 ºF (see 6.6).

(c)

Boiler feedwater (5400 fpm) rotary pump packings.

(1)

The average overall shaft temperature shall not exceed 300 ºF (see 6.6).

Failure to meet any of these criteria shall be cause for disqualification of the packing (see 4.6.5).

3.5.3 Shaft wear. Any single measurement of test fixture shaft wear which is greater than .015 inch (for

Type I, Class A fresh water), .014 inch (for Type I, Class A seawater), .022 inch (for Type I, Class A boiler

feedwater), or .005 inch (for Type II, Class A) shall be cause for disqualification of the tested packing (see 4.6.5.1).

3.5.4 Fixture cavity residue (all types and classes). Any packing residue found in the test fixture cavity upon

completion of the simulated service testing shall be cause for disqualification (see 4.6.5).

3.5.5 Addition of packing rings (Type I, Class A; Type II Class A). When test fixture packing gland takeup

reaches its limits, a one-time single additional ring of packing may be installed, provided the allowable packing

gland leakage rate has been maintained prior to installation of the additional packing ring (see 4.6.5).

3.5.6 Replacement of packing rings (Type I, Class A; Type II Class A). If it becomes necessary to replace

any packing ring because of deterioration or excessive packing gland leakage rate, the packing being tested shall be

disqualified (see 4.6.5).

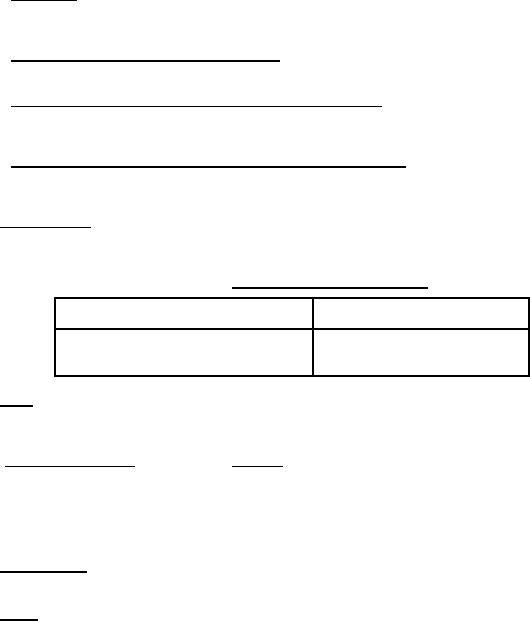

3.6 Size and shape. Packing shall be furnished in the size and shape specified (see 6.2). The shape of the

packing shall be either square or trapezoidal. Allowable tolerances of the cross-sectional dimensions shall be as

specified in table IV.

TABLE IV. Allowable tolerances of packing.

Packing

Allowable tolerance (inch)

cross-sectional dimensions (inch)

±1/64

up to 1/4

1/4 to 1/2

±1/32

1/2 and above

±1/16

3.7 Form. The packing shall be furnished in the form of spools or reels in sizes and lengths as specified by

the procuring activity (see 6.2). The packing shall be uniformly coiled on spools or reels according to the

following:

Packing size (inches)

Package

1/8 through 5/16

1 or 5 pound spools

3/8 through 3/4

5 or 10 pound spools

3/4 through 1

25, 50, or 100 pound reels

1-1/8 through 2

50 or 100 pound reels

3.8 Workmanship. The workmanship shall be such that the packing material shall be free of major defects

which affect its serviceability (see 4.5.1.1).

3.9 Safety. The materials used in the packing, unless specific material maximum levels are cited herein,

shall have no known carcinogenic or potentially carcinogenic materials identified by Occupational Safety and

Health Administration (OSHA) as regulated carcinogens, or International Agency for Research on Cancer (IARC)

latest monographs, or the latest annual report of the National Toxicology Program (NTP); and shall have no

extremely hazardous substances (EHS) or toxic chemicals identified in 40 CFR 355 and 372, respectively. The

manufacturer is responsible for maintaining carcinogenic free, extremely hazardous substance free, and toxic

chemical free materials. The manufacturer shall not, unless specific material maximum levels are cited herein,

allow the addition of any of these prohibited materials to the formulation; and when any of these prohibited

materials are/may be present, as a result of being present as a trace or impurity in another ingredient(s), the

concentration of the prohibited material shall not equal or exceed 0.1 percent by weight of the packing. The rubber

gasket material shall have no adverse effect on the health of personnel when used for its intended purpose.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business